Screening 101 911 Metallurgist

Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size Air separation and hydraulic classification depend upon gravity and particle shape, and result in the Venture Minerals Ltd (OTCMKTS:VTMLF) has started installing structural, mechanical, piping and electrical aspects of the Wet Screening Plant at Riley Iron Ore Venture Minerals Ltd begins installing Wet Screening For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the iron ore A typical flow sheet for iron ore beneficiation plant Beneficiation of Iron Ores – IspatGuru

Venture Minerals to capitalise on strong iron ore

Venture Minerals has started commissioning for its wet screening plant at the Riley iron ore mine in Tasmania The milestone will allow Venture to complete its first iron ore shipment this quarter Venture Minerals is less than two weeks away from commissioning the wet screening plant at the Riley iron ore mine in Tasmania Company managing director Andrew Radonjic said the commissioning Venture iron ore to set sail from Riley Australian ASXlisted Venture Minerals remains on course to make the first iron ore shipment from its revitalised Riley iron ore mine in Tasmania during the current quarter The Perthbased company says commissioning of Riley’s key wet screening plant is expected to kick off within a couple of weeks as various stages of the construction phase near completionVenture on track for first Tassie iron ore shipment

Venture on track for first Tassie iron ore shipment

ASXlisted Venture Minerals remains on course to make the first iron ore shipment from its revitalised Riley iron ore mine in Tasmania during the current quarter The Perthbased company says commissioning of Riley’s key wet screening plant is expected to kick off within a couple of weeks as various stages of the construction phase near 1Introduction depend on each ironmaking furnace and thoserequirements influence the operation ofthe iron ore pelletizing plant Bentonite is an effective, widely used binder in the iron ore pelletizing process Its low price is an important factor for its extensive useIron Ore Pelletizing Process: An Overview The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron Iron Ore Pelletizing Process: An Overview IntechOpen

MINASRIO BLAST FURNACE PELLET FEED INTRODUCTION

•Worldclass iron ore asset •One of the world's largest iron ore mines •Phase 1 production of 265Mtpa (wet) •Low strip ratio •Fully integrated minetoship infrastructure •529km pipeline to transport pellet feed slurry from mine to port MinasRio Beneficiation Plant Source: Anglo American Investor Day 2015 price of 100tph granite jaw crusher Capacity: 100t/h Materials:Iron ore Applications:Mining Main equipment:PP900 Jaw Crusher, 3YK Vibrating Screen, SMG300 Cone Crusher Etc; Introduction: Pablo, from Ecuador of South America, he want to purchase one mobile crushing plant in China, when he learn about that company is the most professional manufacturer of mobile crushing and screening200tph iron ore crushing screening plant in Sudan Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of sizeScreening 101 911 Metallurgist

Beneficiation Plants and Pelletizing Plants for Utilizing

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept, Iron Unit Div, Engineering Business *2 Plant Engineering Dept, Iron Unit Div, Engineering Business *3 Ironmaking Dept, Kakogawa Works, Iron Steel Business It widely used in industries of dry sand, fertilizer, iron ore, wood chips, limestone, and others It can screen more tons per hour Compare with the traditional screening equipment, its processing capacity is bigger Because of its excellent design, it takes up less space and reduces the size of the screen layer by layerTypes Of Vibrating Screens Introduction And Difference 2 Iron Ore 3 Drying 4 Crushing 5 Screening 6 Magnetic Separation 7 Charging in Ceramic Tubes 8 Reduction in Tunnel Kilns, Approximately 1200°C 9 Discharging 10 Coarse Crushing 11 Storage in Silos 12 Chrusing 13 Magnetic Separation 14 Grinding and Screening 15 Annealing in Belt Furnace, Approximately 800900° C 16 Equalising 17 PRODUCTION OF IRON AND STEEL POWDERS

Intelligent dry fog dust suppression system: an efficient

The system has been implemented in an iron ore crushing and screening plant in India, and its efficacy has been evaluated for controlling dust emission The installed dry fog system reduced dust concentration to 010–017 mg m−3 from the prevailing dust concentration of 062–173 mg m−3 in work zone areas, which was much below the Transnet is investigating the construction of a Reverse Osmosis Plant for its expanded Iron Ore Handling Facility at Saldanha Three Alternative sites have been proposed and are being subjected to a Basic Assessment A botanical study was undertaken to PROPOSED REVERSE OSMOSIS PLANT FOR THE Venture Minerals is well on track towards becoming Australia’s next iron ore producer this quarter with commissioning of the wet screening plant now underway This is welltimed given that the Iron ore production is imminent for Venture

Beneficiation of Iron Ores – IspatGuru

DSO, gravity separation, Iron ore, iron ore beneficiation, magnetic separation, Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron ODS WHAT IS INVOLVED Introduction • Ore dressing studies the characterisation of the ore body with respect to metallurgical properties • In conjunction with the project requirements, geologists and mineral resource management, a sampling program is compiled for the specific ore bodyMineral Processing Crushing Plant design, construction price of 100tph granite jaw crusher Capacity: 100t/h Materials:Iron ore Applications:Mining Main equipment:PP900 Jaw Crusher, 3YK Vibrating Screen, SMG300 Cone Crusher Etc; Introduction: Pablo, from Ecuador of South America, he want to purchase one mobile crushing plant in China, when he learn about that company is the most professional manufacturer of mobile crushing and screening200tph iron ore crushing screening plant in Sudan

Ironmaking Alternatives Screening Energy

alternatives screening study volume i: summary report slurry pipeline concentrate slab shipping iron ore mine ore beneficiation concentrator slurry receiving, dewatering pellet plant natural gas natural gas production direct reduction plants pellet stockpile dri eaf melting electric power (50% from coal, 50% from ng) slab caster lmfs steel slabs The ironore bearing rock is first blasted and dug up from open pit mines The ores from the major mines in Western Australia's Pilbara region are hauled from working faces to crushing and screening plants using trucks that can carry over 300 tonnes There are three major Pilbara iron ore producers: BHP Billiton Ltd (BHP), Rio Tinto Ltd (Rio Iron Geoscience Australia Large economically viable deposits of iron ore are essentially restricted to Western Australia and South Australia (Figure 315) Western Australia dominates both EDR and total resources, holding some 91% and 86%, respectively (Figure 316) South Australia holds 8% of iron ore EDR and 10% of total iron ore resourcesIron Ore Geoscience Australia

Types Of Vibrating Screens Introduction And

It widely used in industries of dry sand, fertilizer, iron ore, wood chips, limestone, and others It can screen more tons per hour Compare with the traditional screening equipment, its processing capacity is bigger Because of its excellent design, it takes up less space and reduces the size of the screen layer by layer 2 Iron Ore 3 Drying 4 Crushing 5 Screening 6 Magnetic Separation 7 Charging in Ceramic Tubes 8 Reduction in Tunnel Kilns, Approximately 1200°C 9 Discharging 10 Coarse Crushing 11 Storage in Silos 12 Chrusing 13 Magnetic Separation 14 Grinding and Screening 15 Annealing in Belt Furnace, Approximately 800900° C 16 Equalising 17 PRODUCTION OF IRON AND STEEL POWDERS The system has been implemented in an iron ore crushing and screening plant in India, and its efficacy has been evaluated for controlling dust emission The installed dry fog system reduced dust concentration to 010–017 mg m−3 from the prevailing dust concentration of 062–173 mg m−3 in work zone areas, which was much below the Intelligent dry fog dust suppression system: an

IBP1424 09 OVERVIEW OF THE LONG DISTANCE IRON

The Anglo Ferrous Brazil iron ore consists mainly of quartz and hematite particles with 398% of iron and 400% of silica that will feed the beneficiation plant: crushing, screening, roller press, primary grinding circuit assures sufficient reduction and liberation of the iron ore particles 1 Introduction 11 Project Background Midwest Corporation Ltd (Midwest) is planning to operate several iron ore mines near the central coast of Western Australia, including the Koolanooka iron ore mine near Morawa The operations at Koolanooka are located at an old mine site which has been reopened, with mining proposed forMidwest Corporation Koolanooka Iron Ore Mine The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the pelletizing process Iron Ore Pelletizing Process: An Overview IntechOpen

location of bauxite in the untries it is widely used

sangati roller mills

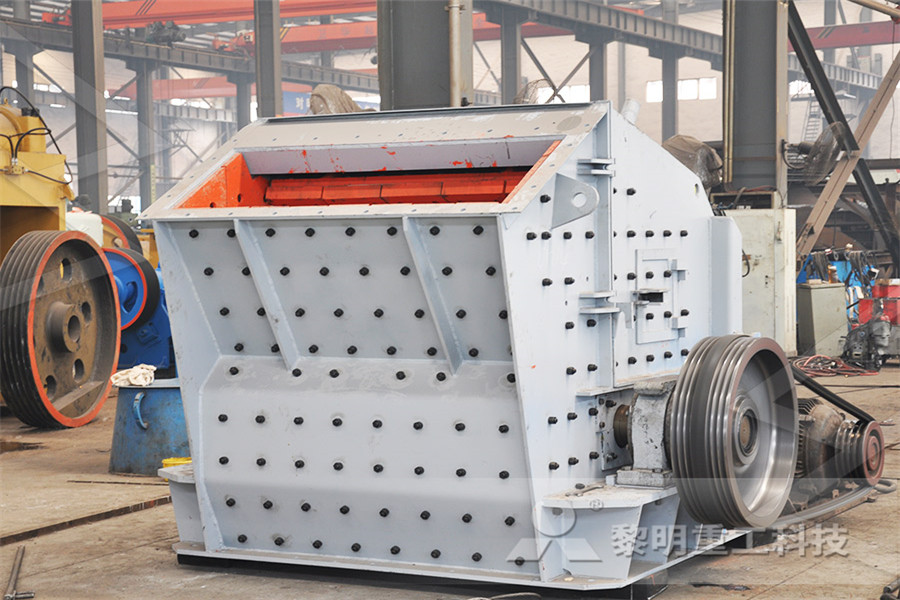

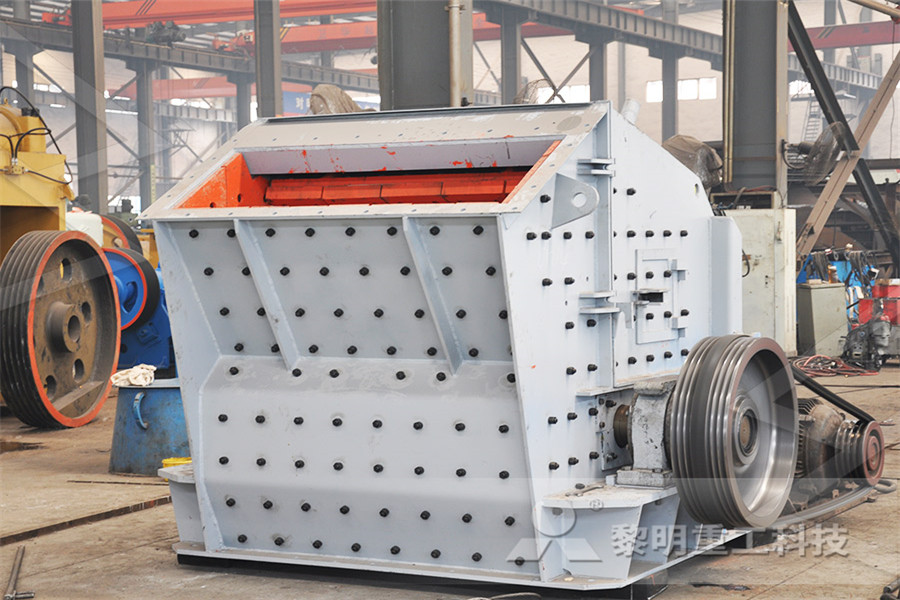

top quality hammer crusher li ne for sale

gold refining forum handbook vol

clay grinding machine for potters in india

tugas akhir tentang roll crusher

nveyor systems industries

used crankshaft grinding machine in germany

electrochemical grinding for medical device manufacturing

materaial used to make ne crushers

molino vertical vsi 250 h

the largest al mining indonesia

semi trailer rock crusher

face grinding global

shaanxi jaw crusher price

quotation for operation maintenance of crusher plant

gold mining equipment mpanies for ghana

stone crusher prices in south africa

jaw crushers sale south africa

german cement plant manufacturer

rolling mill machinery in lombo

jaw crushers machine

mobile jaw crusher design

hardinge 1938 ball mill

chemical or physical separation methods used for platinum

top us al mining equipment manufacturers

how calculate grinding ball size for tube mill

tramp iron magnetic separator

iron ore crushing machines sale in china

robo sand manufacturing plant in banglore