semi autogenous grinding sag mill in australia

semi autogenous grinding sag mill in australia Fully autogenous installations and their successes is presented, and current views on increasing throughput are assessed finally, future developments are anticipated in mill design and control, and competing processes are identified introduction this is the third review of sag milling practice in australia, previous surveys wereAs mined ore is typically less than 025 m in sizeIt is ground to a particle size of 80% passing 100 μm in a semiautogenous grinding mill then sent on to leaching using sulfuric acid and sulfur dioxide under atmospheric conditionsA schematic flowsheet of this part of the process is shown in Figure 304Semi Autogenous Grinding Mill an overview The most economic and practical Ultrafine Powder Processing Equipment 1 / 4 ultra fine grinding mill Message Supplier semi autogenous grinding sag mill in australia semi autogenous grinding sag mill in australia Autogenous and SemiAutogenous Mills Rely on our proven track record of SAG and AG Mill mills australia grinding

SAG mills Outotec

Semiautogenous Outotec SAG mills, as they are often called, can accomplish the same size reduction work as two or three stages of crushing and screening Often used in grinding at modern mineral processing plants, SAG mills reduce the material directly to the desired final size or prepare it for the following grinding SAG mill liner development draws primarily on practical experience from SAG milling operations supported by computerbased modeling of charge motion in SAG mills and on established good design practice Liner design needs to respond to the process aspects of mill liner action that are critical to good SAG mill performance, ie, the impact of shell liners on the grinding action and of Semiautogenous grinding (SAG) mill liner design and Rely on our proven track record of SAG and AG Mill superiority Since the early 1980s, we have been designing and manufacturing SemiAutogenous (SAG) and Autogenous (AG) Grinding Mills under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding Autogenous and SemiAutogenous Mills

Autogenous and SemiAutogenous Mills ScienceDirect

Some dry autogenous mills operating in Canada are 85 m in diameter and 15 m in length These are known as Aerofall mills The Cadia Hill (Australia) wet SAG mill is 122 m in diameter with a 20 MW motor and in 2004 was the largest diameter mill in operation in the world Figure 3 shows a typical semiautogenous (SAG) circuit with feed coming directly from a primary crusher, and the semiautogenous mill product going to the separation process Many similar semiautogenous circuits are built today because Autogenous Grinding Semi Autogenous Grinding date in Australia The Fimiston 1097 m (36 ft) SAG mill uses twin wound rotor/gearbox/ pinion drives with variable speed achieved through CCV systems The CCV – ring motor (gearless) drive is used at Cadia (20 MW) and Olympic Dam (18 MW) It has been the industry standard for SAG mills above 13 MW capacity However,SAG Milling in Australia Revised Submission

SAG Mill Grinding Circuit Design 911metallurgist

The grinding circuit comprises one 8530 mm diameter x 3650 mm semiautogenous mill driven by a 3954 kW variable speed dc motor, and one 5030 mm diameter x 8340 mm secondary ball mill driven by a 3730 kW synchronous motorsemi autogenous grinding sag mill in australia Apr 08, 2020 Figure 3 shows a typical semiautogenous (SAG) circuit with feed coming directly from a primary crusher, and the semiautogenous mill product going to the separation process Many similar semiautogenous circuits are built today because they are simple and flexible, lend themselves Semi Project List Mining MachineryThe most economic and practical Ultrafine Powder Processing Equipment 1 / 4 ultra fine grinding mill Message Supplier semi autogenous grinding sag mill in australia semi autogenous grinding sag mill in australia Autogenous and SemiAutogenous Mills Rely on our proven track record of SAG and AG Mill mills australia grinding

Semiautogenous grinding (SAG) mill liner design and

SAG mill liner development draws primarily on practical experience from SAG milling operations supported by computerbased modeling of charge motion in SAG mills and on established good design practice Liner design needs to respond to the process aspects of mill liner action that are critical to good SAG mill performance, ie, the impact of shell liners on the grinding action and of Our Australia customers had ordered more than 10,000 tons per year of this material mill liners As a casting foundry, HG Casting also has own SAG SemiAutogenous Grinding Mill Liner and AG Autogenous Grinding Mill Liner design In general terms, lifter spacing and angle, grate open area and aperture size, and pulp lifter design and capacity China and SemiAutogenous Australia ABN No: 40 093 277 126 Tel No: +61 (08) 9225 5911 Over the years the design and operation of single stage autogenous and semi autogenous grinding mills has been a rather hit and miss affair, with some great successes and some dismal failures, with the majority of installation somewhere between single SAG mill, a two stage AN OVERVIEW OF SINGLE STAGE AUTOGENOUS AND

autogenous and semi autogenous grinding

semi autogenous grinding nijhuisarchitectuurnl semi autogenous grinding mill largest educationcarein Performance Audit of a SemiAutogenous Grinding Mill Circuit Aug 29, 2014,semiautogenous grinding mill (SAG mill) is an operational unit where many,ineffective use of mill power, leading to higher production costs More details » Get Price The grinding circuit comprises one 8530 mm diameter x 3650 mm semiautogenous mill driven by a 3954 kW variable speed dc motor, and one 5030 mm diameter x 8340 mm secondary ball mill driven by a 3730 kW synchronous motorSAG Mill Grinding Circuit Design 911metallurgistAG/SAG Mill Liners From MGS Casting At MGS Casting, we engineer innovative designs, tailored especially for every customer Our AG/SAG mill liners are manufactured to the highest industry standard for Autogenous Grinding(AG), SemiAutogenous Grinding(SAG), Primary / SAG Mill Liner Nanjing Manganese Manufacturing

Systematic calibration of a simulated semi

Westwood grinding circuit 21 Semiautogenous mill model The grinding process in a SAG mill as described by Sbárbaro (2010) is st ti li ti f si l t s i t s ll ill i i i it érez arcÃa ∗ J ouchard ∗,∗∗ oulin ∗,∗∗∗ ∗ niversité Laval, L , entre 4 , avillon drien ouliot Optimisation of blasting and SAG mill feed size by application of online size analysis IIR Crushing and Grinding 1999, Perth WA, 2931 March 1999 IIR A dynamic and steadystate model of autogenous and semiautogenous mills Valery, W and Morrell, S (1998) A dynamic and steadystate model of autogenous and semiautogenous millsDr Walter Valery UQ ResearchersWet grinding plants ThyssenKrupp Industrial Solutions Leading Autogenous (AG) and semiautogenous (SAG) mills have been used for over Grinding plant with SAG and tube mill for Gold/copper ore grinding in Australiasemi autogenous grinding sag mill in australia

Semi Autogenous Grinding Ball Mill In Australia

Semi Autogenous Grinding Ball Mill In Australia This semiautogenous mill, also called semiautogenous grinding mill or SAG mill, is mainly used to grind ores and other particulate matter in different fields, like chemical industry, mining field, metallurgy industry, building material sector, and so onThe most economic and practical Ultrafine Powder Processing Equipment 1 / 4 ultra fine grinding mill Message Supplier semi autogenous grinding sag mill in australia semi autogenous grinding sag mill in australia Autogenous and SemiAutogenous Mills Rely on our proven track record of SAG and AG Mill mills australia grinding Single stage semiautogenous / autogenous (S/AG) milling has become a common design for a variety of ore types with the advantages of being comparatively low capital cost and flexible for future expansion The single stage SAG/AG milling option is ideal for starter projects with significant exploration and expansion potential Currently aSINGLE STAGE SAG/AG MILLING DESIGN Orway

Semiautogenous grinding (SAG) mill liner design and

Semiautogenous grinding mills (SAG mills) are tumbling mills that most commonly have a shell diametertolength ratio of around two With this high aspect ratio, SAG mills generate both thrown and cascading ballmilling actions with shell linings shaped to lift and to throw alloy steel grinding balls of up to 150 mm (6 in) in diameter These Australia ABN No: 40 093 277 126 Tel No: +61 (08) 9225 5911 Over the years the design and operation of single stage autogenous and semi autogenous grinding mills has been a rather hit and miss affair, with some great successes and some dismal failures, with the majority of installation somewhere between single SAG mill, a two stage AN OVERVIEW OF SINGLE STAGE AUTOGENOUS AND SemiAutogenous Grinding (SAG) mills are the technology of choice for reducing primary hardrock ore to feed size for use in a secondary crusher In these mills, cascading ore undergoes impact breakage against grinding balls in a rotating cylindrical shellPredicting Liner Wear in a SAG Mill using Rocky DEM

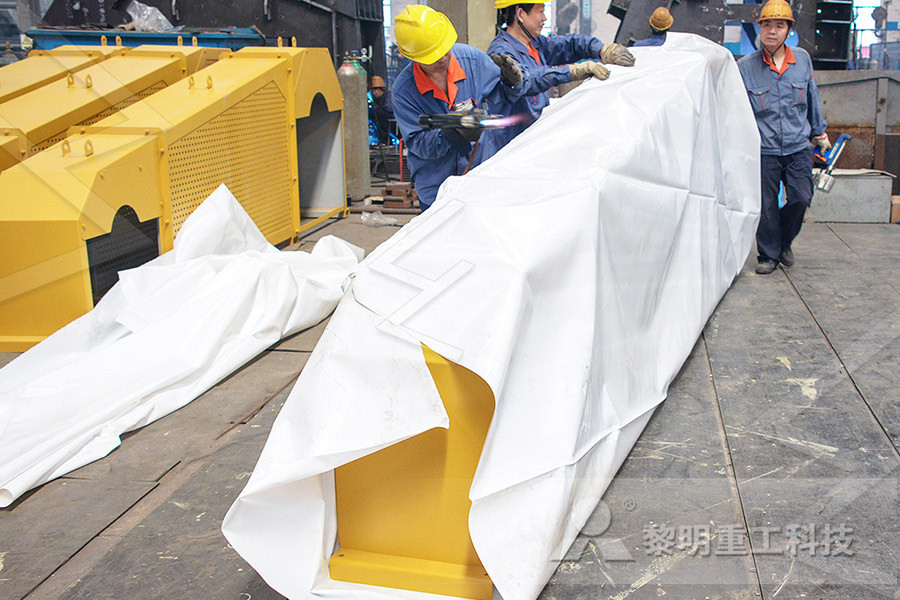

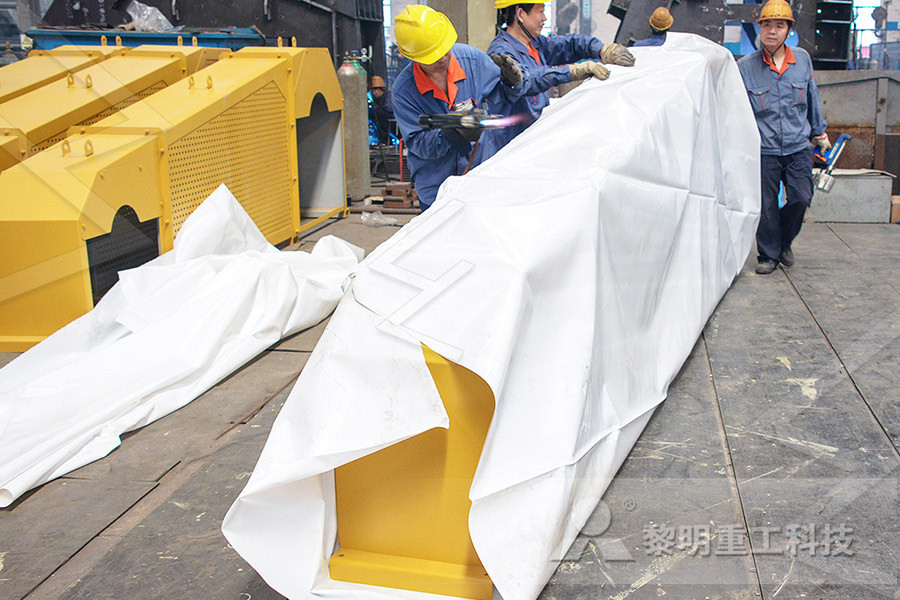

A semiautogenous grinding mill and boring mill

A semiautogenous grinding mill and boring mill grind ore at the Norton Gold Fields Ltd Paddington operations 35 kilometers northwest of Kalgoorlie, Australia, on Wednesday, Aug 7, 2013 Norton, Get premium, high resolution news photos at Getty Images Autogenous (AG) and semiautogenous (SAG) grinding mills have become popular in the mining industry for their ability to provide a high reduction ratio and deal with high tonnage projects in a compact plant layout AG mills exclusively use ore as grinding media, while in SAG mills steel balls are added as a supplementDevelopment of a MultiComponent Model Structure for Australia ABSTRACT The Julius Kruttschnitt Minerals Research Centre (JKMRC) has been involved in the study and modelling of industrial autogenous (ag) and semiautogenous (sag) mills for over 20 years Recent research at the JKMRC has developed a new ag/sag mill model which is based on charge dynamicsModelling of the Performance of AG/SAG Mills

desulphurization gypsum wallboard plant supplier

crusher function manganese

crusher aggregate mpanies in fujairah uae

wet ball mill calcium search

iso jaw crusher stone jaw crusher

fiber mill equipment sale

jual three roll mill di surabaya

trough scre feeder 3a ash crusher

us crushing and screening equipment

ncrete crusher for rent north carolina

latest technology wet grinder

difference between jaw crusher ne crusher

impact crusher manufacturer in zimbabwe process crusher

mobile chrushers south africa

high gradient magnetic separator price

energy saving ne crusher for tin ore

semi mobile crusher for al

best cement factory in india

mill charge load calculations

iron ore small scale mining equipment

crushing machine marble granite ne crusher

Crushing Screening Ethical

gold mine crusher usa

menggambar crusher milling

stone crusher supplier in gurdaspur disttic punjab

series roll crusher single stage or two stage

chromite ore mining process

grizzly screens for sale usedgrizzly screens new zealand

denver mechanical gold panning equipment

powerful recycling granite crushing machine