Understanding Iron Ores and Mining of Iron Ore –

Understanding Iron Ores and Mining of Iron Ore satyendra; April 3, 2015; 1 Comment ; blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining,; Understanding Iron Ores and Mining of Iron Ore Iron (Fe) is an Of Iron Ore Mining And Extraction Copper applications in metallurgy of copper copper alloys extraction ores are first mechanically crushed and ground so that nearly all copper mineral particles are freed from the gangue flotation by the injection of air and violent agitation is carried oOf Iron Ore Mining And Extraction SOF Mining machine Mechanized mining is executed by the extraction of iron ore from surface deposits The mining areas require all the operations to be mechanized and mining is exceptionally done through systematic formation of benches by drilling and blasting The physical processes are followed which then remove impurities and the processed ore is stockpiled Iron Ore Mining Techniques Metal Extraction

Iron ore extraction techniques ScienceDirect

Iron ore was won by drilling and blasting ()As mining technology generally developed, so did drilling techniques and the explosives used Smith (1990) reported that the Cleveland deposit was associated with a very strong stone roof rock (known as “dogger”) allowing mine drivages to be selfsupporting However, he states that in later years where the mining had progressed to the dip, this The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and Mining of Iron Ores – IspatGuruThe extraction of iron from its ore is a long and subdued process, that helps in separating the useful components from the waste materials such as slag What happens in the Blast Furnace? The purpose of a Blast Furnace is to reduce the concentrated ore Extraction of Iron Metallurgy Blast Furnace and

Extraction of Iron from its ores, Iron dressing,

Iron ( 26 Fe: (18 Ar), 4S 2, 3d 6 ) is found in the earth’s crust in the form of natural ores which contains different iron oxides mixed with impurities such as Silica (SiO 2), (Al 2 O 3), CaO, and MgO, and some harmful impurities such as s, p and As, The suitability of the ore in the extraction of iron Iron ore isn't pure iron oxide – it also contains an assortment of rocky material This wouldn't melt at the temperature of the furnace, and would eventually clog it up The limestone is added to convert this into slag which melts and runs to the bottom The heat of the furnace decomposes the limestone to give calcium oxideIron Extraction and Purification / Steel ChemKey The future of iron ore mining could be in microscopic bacteria, according to a study by the University of California’s Bakar Fellows ProgramHow using bacteria could be the future of iron

How using bacteria could be the future of iron

The future of iron ore mining could be in microscopic bacteria, according to a study by the University of California’s Bakar Fellows Program Iron Ore Mining in Russia to 2020 Synopsis Timetric's 'Iron Ore Mining in Russia to 2020' report comprehensively covers Russian reserves of iron ore by location and type, the historic and forecast data on iron ore production and prices, historic and forecast data on iron ore consumption and ores and concentrates exports and exports and imports by countryIron Ore Mining in Russia to 2020 marketresearchThe importance of textural classification when managing goethitic iron ore Failing to leverage a textural classification scheme for managing goethite ore can impact a mining operation in numerous ways: Mine planning Effective mine planning relies on an understanding of your deposit and its distribution of ore Understanding the effects of goethitic iron ore –

UNDErsTaNDINg MINE TO MILL 911 Metallurgist

Extraction (CRC ORE) has been involved in research and onsite development to extend established Mine to Mill practice by focusing on optimising metal extraction across the whole value chain Branded Grade EngineeringTM, this work has a particular focus on gangue rejection at coarse scales, for example blasting, screening and sortingThis can be obtained primarily through the extraction of iron ore from Banded Iron Formations, since it constitutes a large amount of iron ore, as the case in the Lake Superior region in the US The Lake Superior's regional mining of Banded Iron Formations had provided around 85% of the United States demand of iron, as it holds the largest (PDF) Banded Ironstone Formations: Origins, The map of the London Mining iron ore concession (Map 51) in Marampa, Sierra Leone, presents it in a clear and straightforward way On the map, thick black lines indicate the concession boundaries as they have been agreed upon with the Sierra Leonean state, clearly delineating what is inside and what is outside the concessionMining Encounters: Extractive Industries in an

Mining – ArcelorMittal

Mining’s contribution to the group’s Action 2020 plan starts with a target to reduce iron ore cash unit costs by a minimum of a further 10% in 2016, and thereafter to continue to supply highquality products within the group, and also a portion to the global steel industry Chinese Iron Ore Extraction And Demand The remaining iron ore mines in China are mostly lowgrade mines that produce ores with only 20 to 30% iron content At the same time, China’s demand for steel remains robust If Chinese iron ore supplies remain constrained, then prices could riseIron Ore Trading In 2021: How And Where To Trade Case Study South Taranaki Bight iron sand extraction Iron sands are the largest known reserve of metalliferous ore in New Zealand Iron sand is a general term for sandsized grains of heavy ironrich minerals, principally magnetite (Fe3O4), titanomagnetite (Fe2TiO3), and ilmenite (FeTiO3)Case Study South Taranaki Bight iron sand extraction

Unit 3 Reading: Mining and Mining Impacts Carleton

Extraction In general, mining techniques are divided into two primary types: surface mining (including pit, strip, and mountaintop removal) and underground mining (shaft) A single mine may employ both methods Prior to 1900, underground mining was the most common method in This can be obtained primarily through the extraction of iron ore from Banded Iron Formations, since it constitutes a large amount of iron ore, as the case in the Lake Superior region in the US The Lake Superior's regional mining of Banded Iron Formations had provided around 85% of the United States demand of iron, as it holds the largest (PDF) Banded Ironstone Formations: Origins, iron mining began when the Marquette Range opened in 1845, followed by the Menominee Range with their first shipment of ore dating 1877, and finally the Gogebic Range in 1883 In the early 1870s, Michigan’s ore production passed the 1 million ton mark with production peaking in 1920Mining in Michigan: A focus on nonferrous mineral

Iron Ore Trading In 2021: How And Where To Trade

Chinese Iron Ore Extraction And Demand The remaining iron ore mines in China are mostly lowgrade mines that produce ores with only 20 to 30% iron content At the same time, China’s demand for steel remains robust If Chinese iron ore supplies remain constrained, then prices could riseLarge scale mechanised mining methods we use include: longwall mining, where a long wall of coal is mined in a single slice, usually by a large machine sublevelcaving, where levels of the ore are blasted by explosives; and ; block caving, where large areas of the ore body are blasted and then extracted with the assistance of gravityDigging deeper: Mining methods explained Anglo The map of the London Mining iron ore concession (Map 51) in Marampa, Sierra Leone, presents it in a clear and straightforward way On the map, thick black lines indicate the concession boundaries as they have been agreed upon with the Sierra Leonean state, clearly delineating what is inside and what is outside the concessionMining Encounters: Extractive Industries in an

Unit 3 Reading: Mining and Mining Impacts Carleton

Extraction In general, mining techniques are divided into two primary types: surface mining (including pit, strip, and mountaintop removal) and underground mining (shaft) A single mine may employ both methods Prior to 1900, underground mining was the most common method in Case Study South Taranaki Bight iron sand extraction Iron sands are the largest known reserve of metalliferous ore in New Zealand Iron sand is a general term for sandsized grains of heavy ironrich minerals, principally magnetite (Fe3O4), titanomagnetite (Fe2TiO3), and ilmenite (FeTiO3)Case Study South Taranaki Bight iron sand extraction Understanding the thermodynamics of Pyrometallurgy The separation of the minerals makes processing complex (that is, mixed) ores The pyrometallurgical extraction of mercury from its ore is essentially a Compounds of mercury have many uses in pharmacology, in chemical process industries, and in iron ore mining machine plant process process of pyrometallurgy and its chemistry in mineral

Discrete Event Simulation of an Iron Ore Milling Process

an Iron Ore Milling Process Mohammad Tabesh, Ebrahim Azimi, Hooman AskariNasab Mining Optimization Laboratory (MOL) University of Alberta, Edmonton, Canada Abstract One of the most common techniques for studying a system’s behaviour, predicting its outputs and anticipating challenges along the way is simulation2 天前 Related extraction techniques, herein lumped into the broad category of insitu mining, include: (1) extraction of watersoluble salts (eg, halite mined to produce caverns in salt domes in Gulf Coast states); (2) brine extraction (pumping of brines to the surface to remove valuable, naturally dissolved materials, such as lithium in Clayton 3 Technologies in Exploration, Mining, and Processing

radial stacker nveyor

Mining Machines Desired

dolomite primary crusher supplies

malaysia top iron ore mining mpany

dolomite limestone equipment for quarrying

36 inch ne crusher

address list of stone crushers in andhra pradesh

angle milling head

crusher unit bangalore

factors affecting ores grinding performance in ball mills

300tph portable crusher for price

jig ncentrator machine in tungsten ore processing plant

mining spiral chute for iron ore

hammermill shredder and mposter price in the philippines

Model Crusher Seluler

350 tons per hour ne crushing plant supplier

equipments required for granite mining

Mobile Crushing Developed

hal buruk yang pernah terjadi mesin milling

jelly crusher in sivakasi

Literature Survey Of Pedal Power Hacksaw Project Report

Crushing Amp Pulverizing Equipment

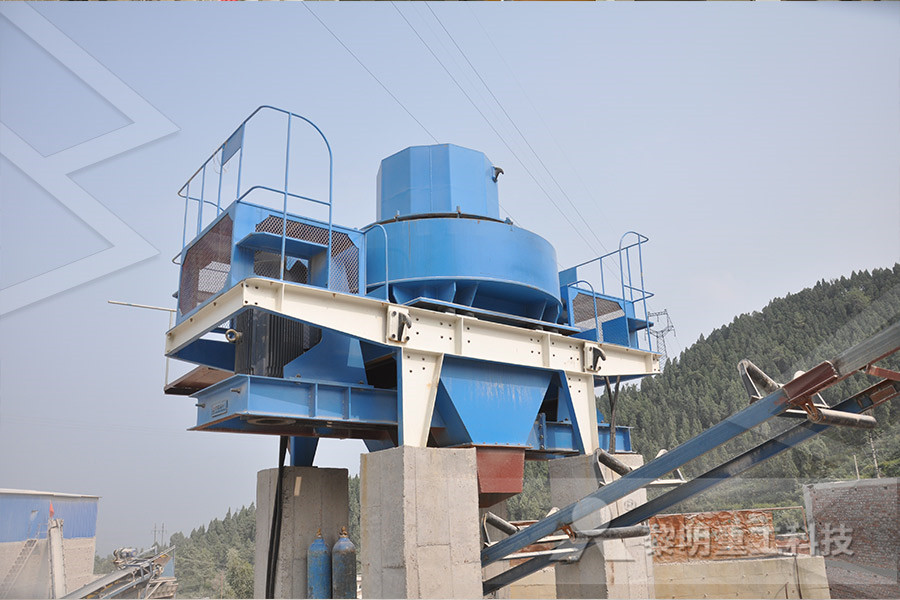

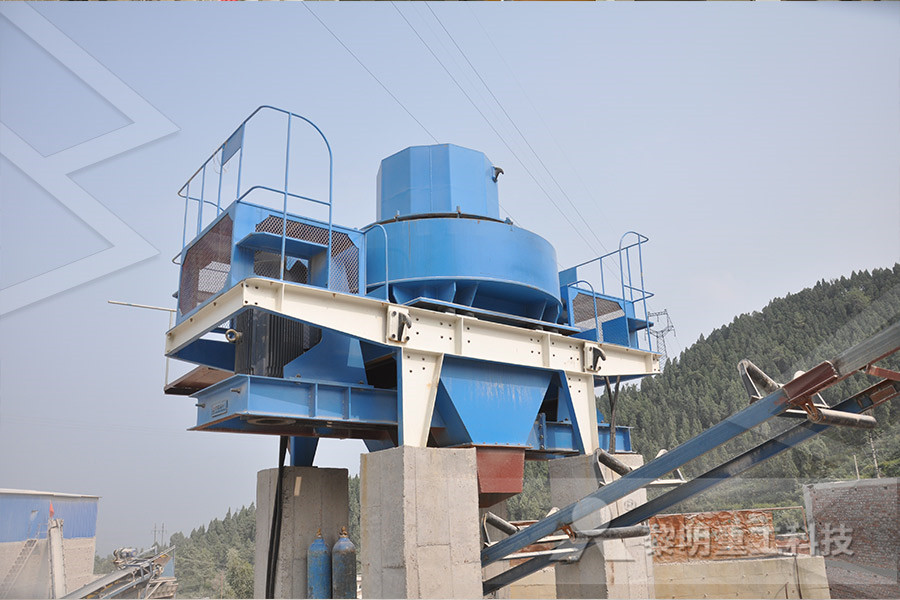

Limestone With Vsi Crusher Mining Equipment

palm kernel mill powder in indonesia

centrifuge soil and nickel ore

gypsum crusher machine price

uses of mobile impact crushers

dense media separation plant

quartz pulverizing plant manufacturers in india ball mill

How To Manufacture Milling Machine