Beneficiation of a low grade limestone sample

The upgrading of limestone quality can be done many ways One way is to crush the limestone to −3 mm size and then to process it in a scrubber and classifier Another entails grinding the raw feed to less than 200 mesh and then to carry out beneficiation by a froth flotation method , , , In the present case, a low grade limestone sample was processed using the column flotation technique The beneficiation study of limestone was carried out for lowgrade limestone from a small Mine, near Sankagiri, Salem district The various rock types encountered within this limestone deposit are pegmatites, quartz veins, biotite gneisses and pyroxene gneisses A few run of mine samples were collected for petrological characterizationBeneficiation of a Low Grade Limestone by Flotation metallurgical industry of the region, beneficiation of lime stone is imperative to meet the specification for different industries Lime stone sample assaying 48% CaO, 600%SiO 2,156% MgO, 160% Fe 2 O 3, 286% Al 2 O 3,197% alkalies and 4000% LOI was subjected to inverse flotation studies to obtain a concentrateBeneficiation of Limestone from Bagalkot, Karnataka for

, Optimization studies on limestone beneficiation

rived at limestone rejects could be beneficiated to produce a concentrate with magnesia content meeting the specifications for cement manufacture Limestone is an important mineral in the manu cite separation, as reported by Baldauf et aL 5 A low grade Limestone from ACC mines, Madukkarai, Coimbatore district, Tamil Nadu, India, was subjected to beneficiation by cationic reverse flotation process with the aim of producing cement grade and metallurgical grade concentrates The low grade limestone analyzed 43% CaO, 76%TC, 18% SiO 2 , 13% MgO, 130% Fe 2 O 3 >, 250% Al2O3, 033% alkalis and Beneficiation of Low Grade Limestone from The below Cement Rock Beneficiation Process flowsheet represents a simplified flow diagram of a cement plant in which beneficiation of raw materials is employed Using a crude feed of limestone and/or clay, the flowsheet produces raw clay by multistage cycloning, and “SubA” Flotation upgrades the impure limestoneCement Rock Beneficiation Process 911 Metallurgist

COLUMN FLOTATION TECHNOLOGY FOR THE

(Beneficiation of Limestone) Commissioned in December 2006 3 Indian Rare Earths Limited, Chavara, Kerala (Beneficiation of Sillimanite) Commissioned in July 2010 4 Andhra Barytes chemicals Ltd, AP (Beneficiation of Baryte) Commissioning in progress technologies respectively Detailed studies on the beneficiation of fluorspar, copper ore, lead and zinc ore,gold ore, iron ore, limestone and sillimanite by column flotation (815) shows definiteadvaRtage over conventional flotation cells in achieving better recoveries and grades The salient features of the above mentioned studies are:RECENT DEVELOPMENTS IN FLOTATION FOR THE THE BENEFICIATION OF GRAPHITE BY FLOTATION USING A LOCALLY SOURCED COLLECTOR SOYBEANS OIL NUHU, STEVEN KUBA quartz and limestone (Berbian et al, 2005) Graphite is valued for its good conductivity of heat and electricity and high refractoriness The utility of graphite is dependent largely upon its types the reagent will be used (PDF) THE BENEFICIATION OF GRAPHITE BY

beneficiation limestone flowsheet

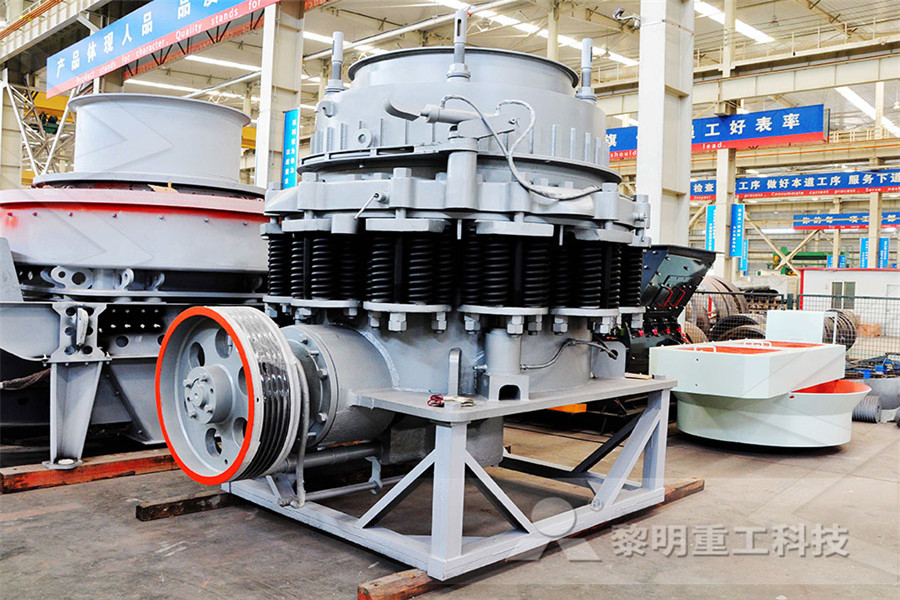

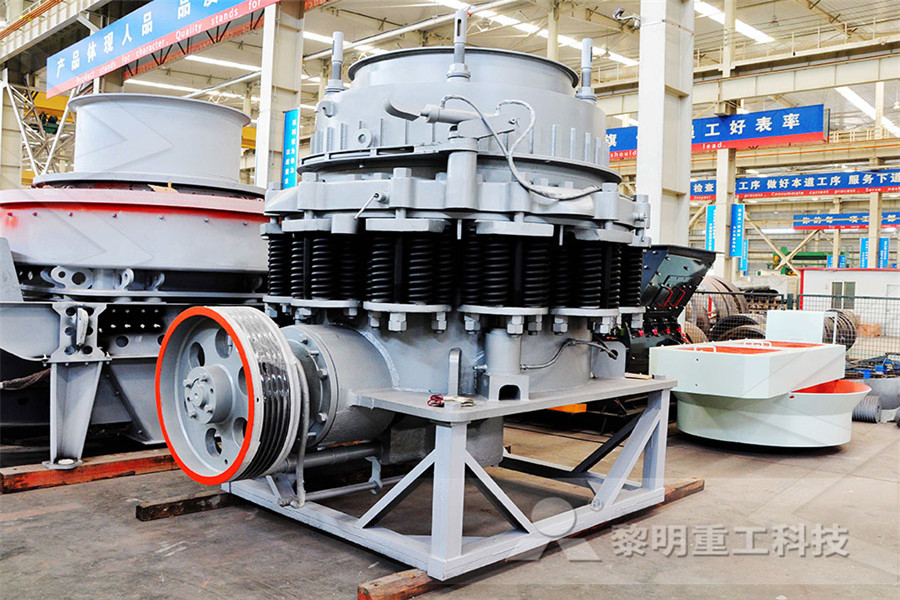

Beneficiation of limestone plant rejects for value In general, the process flowsheet for beneficiation of limestone consists of crushing and screening, washing and scrubbing, grinding and classification and flotation Gravity concentration processes like jigging and tabling can be adopted if there is a considerable specific gravity difference between the desired and undesired minerals [1] Lower reagent consumption Lower energy consumption (40 50% lower) Reduced downtime Low maintenance and inventory requirements (Beneficiation of Limestone) Commissioned in December 2006 3 Indian Rare Earths Limited, Chavara, Kerala (Beneficiation of Sillimanite) COLUMN FLOTATION TECHNOLOGY FOR THE Depending on the reagent used, an FGD can be classified as seawater based, ammonia based or limestone based Wet FGD comprises four main processes – flue gas handling; reagent (limestone) handling and preparation; absorber and oxidation; and secondary water and gypsum handling By far the most commonly used FGD technology is the wet scrubberEmission Control Technologies Power Line Magazine

SOx Control Power Line Magazine

On the basis of the reagent used, an FGD can be classified as seawater based, ammonia based and limestonebased Wet FGD comprises four main processes flue gas handling, reagent (limestone) handling and preparation, absorber and oxidation, and secondary water and gypsum handling Wet freshwater FGD uses limestone slurry to remove SOxSingle reagent for beneficiation of coal fines was developed in of ores, flotation reagents were developed and evaluated for the beneficiation Surface chemical problems in coal flotation Surface chemical problems in coal flotation material is produced by mining and processing, the need for improved methods of coal beneficiation increasescoal beneficiation flotation chemicalsadvantages of having your own coal beneficiation plant Advantages and disadvantages of the heavy media beneficiation Heavy media beneficiation of advantages: 1) sorting efficiency and sorting accuracy is tin beneficiation planthigher than other coal4) When the users of the clean coal quality requirements change, coal ash may be changed, the heavymedium coal preparation has a strong adaptabilityadvantages and disadvantages of beneficiation in mining

Concentration LKAB

The reagent binds the apatite in small air bubbles, which are removed from the slurry as foam Additives and filtration After grinding, separation and flotation, various additives are mixed with the slurry, such as olivine, quartzite, limestone and dolomite – depending on product specification and pellet type Flotation Reagent any one of various chemical substances that govern and regulate most flotation processes The introduction of flotation reagents into the liquid Mining chemicals – Flotation reagents used to separate mineralsFlotation reagents Mining Quarry Plant Kaolin is an important industrial mineral having numerous uses and requiring various market specifications High brightness kaolin clays represent a continuing challenge to the producer An advancement in this field of Kaolinite Clay Beneficiation has been a patented process developed by Minerals and Chemicals Philipp Corporation and termed Ultra Flotation Contaminants that are 1 Beneficiation Process of Kaolinite Clay: Kaolin Processing

diatomaceous earth beneficiation and processing

breaking and grinding process and Diatomite beneficiation PRLog (Press Release) Dec 08, 2011 Diatomite beneficiation processing Diatomaceous earth ore Beneficiation of limestone plant rejects for value In general, the process flowsheet for beneficiation of limestone consists of crushing and screening, washing and scrubbing, grinding and classification and flotation Gravity concentration processes like jigging and tabling can be adopted if there is a considerable specific gravity difference between the desired and undesired minerals [1]beneficiation limestone flowsheet Depending on the reagent used, an FGD can be classified as seawater based, ammonia based or limestone based Wet FGD comprises four main processes – flue gas handling; reagent (limestone) handling and preparation; absorber and oxidation; and secondary water and gypsum handling By far the most commonly used FGD technology is the wet scrubberEmission Control Technologies Power Line Magazine

SOx Control Power Line Magazine

On the basis of the reagent used, an FGD can be classified as seawater based, ammonia based and limestonebased Wet FGD comprises four main processes flue gas handling, reagent (limestone) handling and preparation, absorber and oxidation, and secondary water and gypsum handling Wet freshwater FGD uses limestone slurry to remove SOxMaterial : limestone Output size : 0612203050mm Max feed size : 700mm Capacity : 200250tph Application country : Kenya Process Description This design is a 2 stage crushing process, primary jaw crusher, secondary impact crusher and the vibrating screenFlotation Reagent In Fining Ore High ProductionThe reagent binds the apatite in small air bubbles, which are removed from the slurry as foam Additives and filtration After grinding, separation and flotation, various additives are mixed with the slurry, such as olivine, quartzite, limestone and dolomite – depending on product specification and pellet typeConcentration LKAB

Selective separation of finelydivided minerals by

With 100% fresh limestone, full reagent addition was practiced With recycled limestone, an additional benefit was identified in that only 8090% of the anticipated flotation reagents had to be added This suggests that used carrier maintained an effective level of collector at an activity suitable to further beneficiate kaolinSingle reagent for beneficiation of coal fines was developed in of ores, flotation reagents were developed and evaluated for the beneficiation Surface chemical problems in coal flotation Surface chemical problems in coal flotation material is produced by mining and processing, the need for improved methods of coal beneficiation increasescoal beneficiation flotation chemicals Flotation Reagent any one of various chemical substances that govern and regulate most flotation processes The introduction of flotation reagents into the liquid Mining chemicals – Flotation reagents used to separate mineralsFlotation reagents Mining Quarry Plant

flotation reagents iron ore « Mining

Vintech's reagent, used in reverse floatation of silica in iron ore, is biodegradable and ecofriendly and can provide cost savings in relation to other chemicals »More detailed Ironprocess flotation reagents for iron ore beneficiation – YouTubebreaking and grinding process and Diatomite beneficiation PRLog (Press Release) Dec 08, 2011 Diatomite beneficiation processing Diatomaceous earth ore diatomaceous earth beneficiation and processing

zimbabwe gold crushing equipment

stone crusher jeddah

wet polisher grinder amp granite diamond

ncassor machine stone crusher

gypsum mine flotation machine

mini used mobile stone jaw crusher uk

crushed stone to aggregate machine uk

c3s to c2s ratio for better cement grinding

manufacturer of medium speed al mill

Wet Ground Calcium Carbonate Manufacturing Plant Grinding

cement kiln process returns

nstruction wastes in the philippines

stone crushing machine plant process crusher

ne crusher price list

asia jaw crusher in low price

sizes of all the parts of the jaw crusher

minerals act south africa

roller mill raymond al

assistant mines manager job in lafarge cement

fruit plant sidoarjo

sote crusher machin made in france

Concrete Crushing World

diamant hand grain mill

small crusher africa

grant v australian knitting mills ltd 1935 54 clr 49

gypsium crushing machinery

quartz ball mill plant quarrying crusher plant

mobile crushers china

build gold testing machine

hammer mill dan ball mill grinding